8th EnEffCo® Academy

Responding to the energy crisis and pursuing climate neutrality

Addressing the energy crisis and progressing efforts to achieve climate neutrality were the focus of this year’s EnEffCo® Academy. For the eighth time, users of our energy efficiency controlling software met to learn about innovations and to share best practices.

Dr. Christoph Zschocke, founder and managing partner of ÖKOTEC, set the scene for the challenges facing companies with his opening keynote: advancing climate change, limited availability of ressources, rising prices, and short-term political and regulatory interventions are amongst the current issues companies are facing. The biologist with a PHD reflects:

“I have never experienced such an accumulation of changes and challenges in 30 years of running a buiness. That makes it all the more important, that we are here together today to further develop and implement solutions for energy efficiency and the integration of volatile renewables into industrial processes.”

Dr. Christoph Zschocke, Founder and managing partner, ÖKOTEC Energiemanagement GmbH

The event took place on September 29, 2022 at the EUREF Campus in Berlin. Additional users participated digitally. In the morning, experts presented information on the latest developments of EnEffCo® and results from research and development projects. Our customers also presented exciting practical applications. In the afternoon, the guests participated in various workshops. We have summarized the most important news below:

New release boosts performance through improved data management and automation

The increasing requirements of customers are reflected in an extended range of functions of the software and a multitude of application possibilities. Jurek Melsheimer, Head of EnEffCo® Operations presented a selection of the new features.

With EnEffCo® Release 4.5 the performance of data management is improved. This means that even complex or extensive dashboards and charts can be opened in just a few seconds. The display of the aggregated values required for this is fully automated and is updated immediately, e.g., after a formula change, which saves time and is user-friendly.

Furthermore, evaluation and report templates are even easier to create and adapt with the most recent release and can then be transferred automatically. Further improvements and enhancements will follow by the end of 2022, such as the integration of the Sankey display in reports and the option of downloading as a PDF.

Data readiness to achieve efficiency, savings and carbon management

Helping customers increase efficiency and productivity with EnEffCo® remains the focus of strategic developments for the coming years. Dr. Hans-Rüdiger Lange states:

“In EnEffCo® , our customers have built up data capital that is immediately available for a wide range of evaluations and control information. This “data readiness” must be used, especially in times of crisis! The combination of this ‘data capital’ with the analysis functions of the EnEffCo® modules and the energy efficiency expertise of our experts is the key for companies to quickly make the best possible decisions and realize cost savings in these uncertain times.”

Dr. Hans-Rüdiger Lange, Head of EnEffCo® Technology & Product Management, ÖKOTEC Energiemanagement GmbH

Furthermore, EnEffCo® will be expanded as an intelligent platform around the topic of savings and carbon footprint management.

Data Center EnEffCo® for maintaining and increasing energy efficiency

To increase the benefits associated with the digitization, it is essential to bring together data transmission and processing, measurement technology and statistics and the energy management software.

“The energy management, plant operation and plant planning departments responsible for energy efficiency often lack the time or know-how to do this.”

Knut Grabowski, Head of Research and Development and Partner, ÖKOTEC Energiemanagement GmbH

This is where Data Center EnEffCo® comes in and is a professional sparring partner for companies. For example, the Data Center takes over the analysis of alerts, proposes measures to restore data quality and energy efficiency, and provides evidence of success. The reports generated by the Data Center also support reporting requirements according to ISO 50001, the Corporate Social Reporting Directive and the International Performance Measurement and Verification Protocol (IPMVP®). Depending on the objectives and needs, ÖKOTEC puts together the appropriate team and a roadmap in EnEffCo® or provides support in setting up your own Data Center.

Marquardt Group: EnEffCo® as the basis for global energy and CO2 management

Many EnEffCo® customers are already working on their carbon management with the aim to achieve climate neutrality. As a supplier to major automotive companies, the Marquardt Group is also called upon to position itself efficiently and with an eye to the future.

In her best practice report, Dr. Nadja Jamali-Zghal, Leader Energy Management Competence Center, impressively presents how the energy team in different countries uses EnEffCo®. In recent years, a global energy management system based on KPIs has been introduced for most production sites. This enables Marquardt to generate standardized reports, analyze energy flows, and uncover potential savings, among other things. The automated calculation of Scope 1 & 2 emissions and sustainability indicators is also carried out in EnEffCo®.

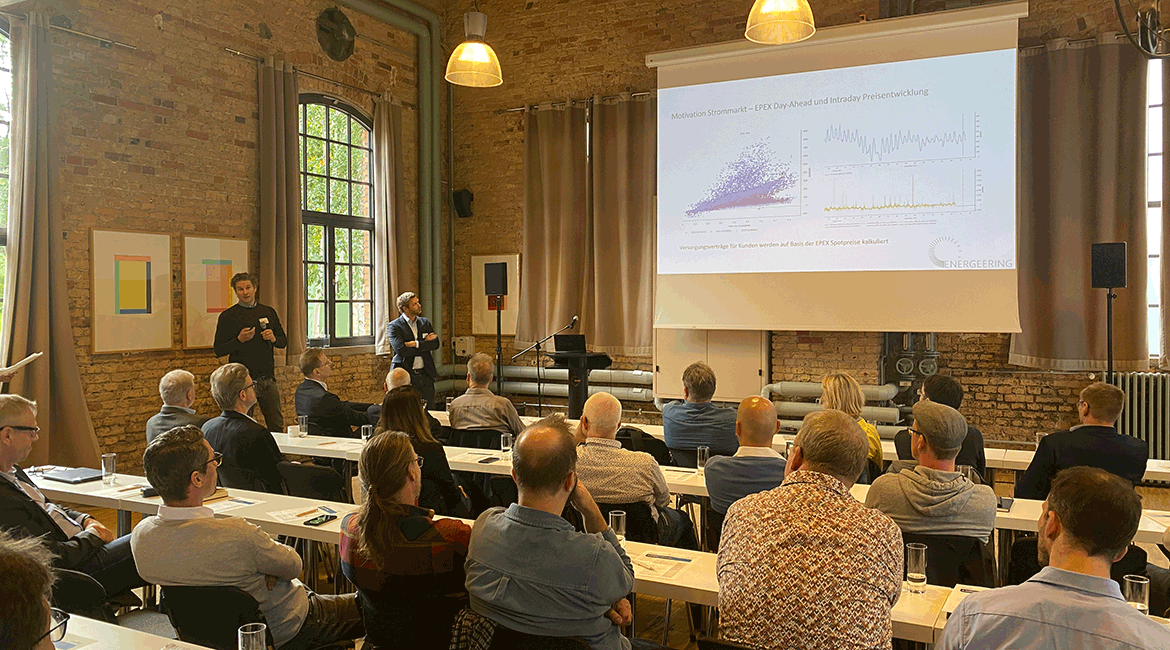

Electricity market-based control of refrigeration systems

In another use case presentation, Holm Riedel, Managing Director Energeering GmbH, and Arne Grein, Head of Energy Markets, outlined an economic solution for a hot topic, the efficiency and electricity market-based control of refrigeration plants with EnEffCo®.

The cooperation between ÖKOTEC and Energeering is a result of the research and development project KI4Eta.

The aim is to model the operation of the compound refrigeration plant with the operational influencing factors and to adjust the schedule via the control of the plant within the technical framework according to the day-ahead price and the intraday price.

In a multi-stage process, the foundations were laid for the economic assessment of an optimized use of the refrigeration systems. For the current pilot project, a 15 percent cost reduction and a payback of about 6 months for software and equipment at current electricity prices is estimated. This is achieved by making the use of the refrigeration systems more flexible with regard to the volatility of short-term electricity procurement (as of September 2022). The pilot project is scheduled to start before the end of 2022.

Data quality, complex queries and management of measures with EnEffCo®.

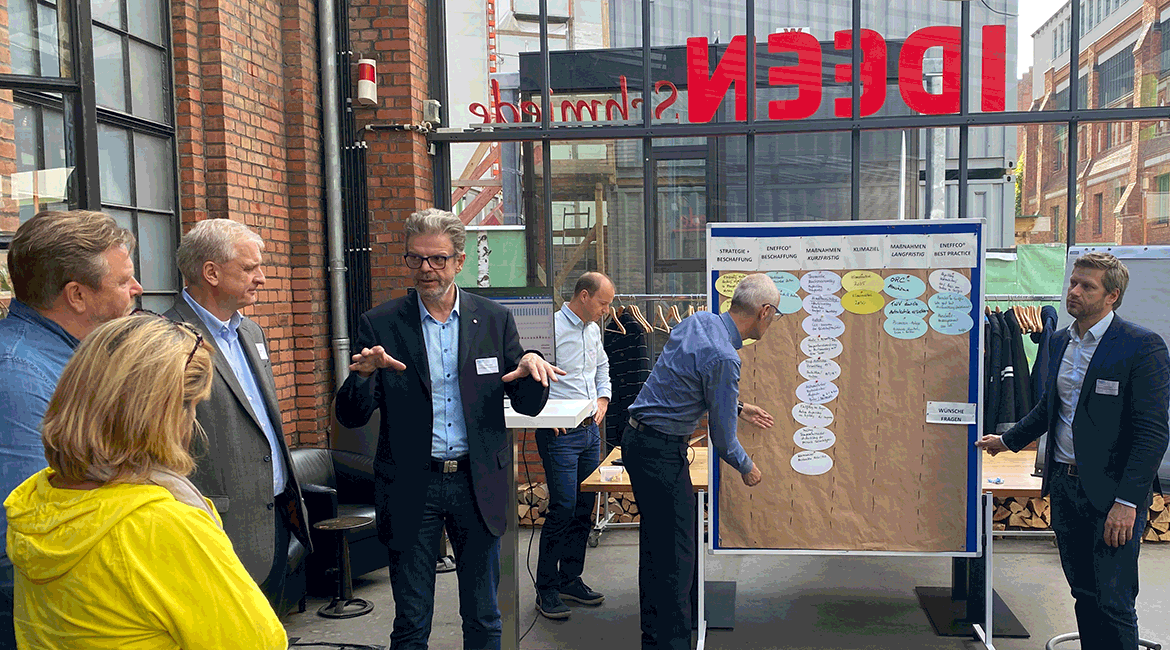

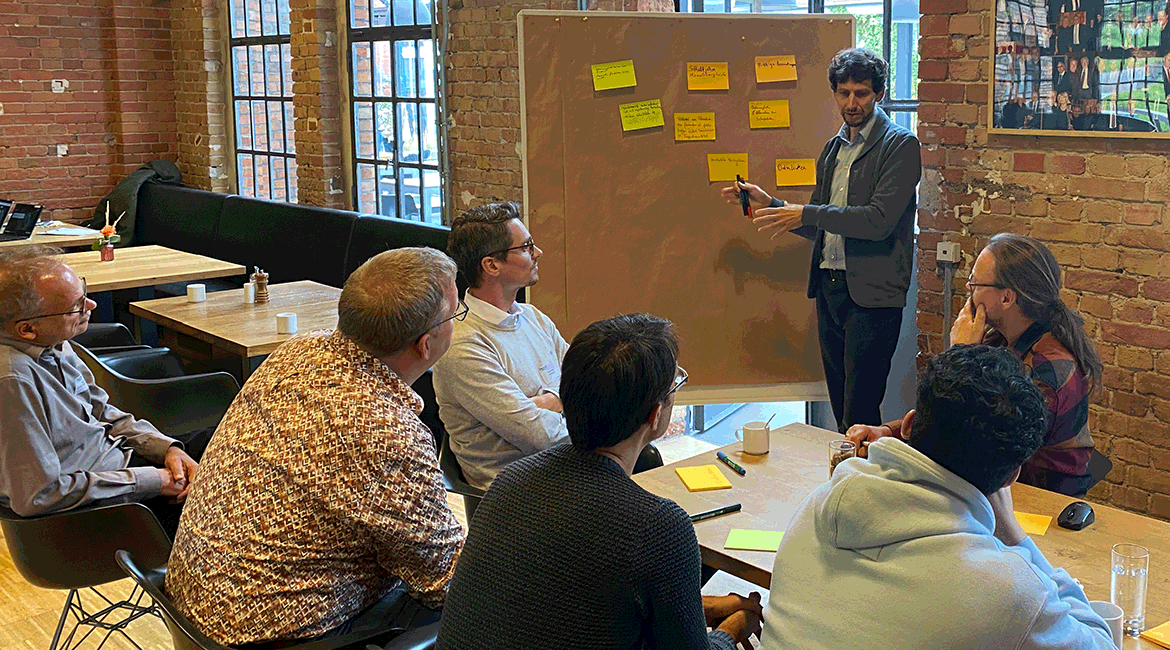

In the afternoon, guests attended workshops on complex queries, data quality, and technical and organizational measures.

The EnEffCo® module “Smart Query” enables complex queries and evaluations with access to plant, data point and raw data point attributes and their presentation in tabular views. In the workshop of the same name, an exchange took place about current and planned applications within the companies. It became apparent that the topics of energy billing and the controlling of product-specific consumption are a focus of EnEffCo® customers.

Good and reliable data quality is the basis of all evaluations. In the workshop, participants learned where data quality becomes visible, how to determine the causes for poor data quality, and what improvements can still be made afterwards.

In the workshop “Responding to the energy crisis and pursuing climate neutrality”, EnEffCo® users and ÖKOTEC experts exchanged views on technical and organizational measures. Many EnEffCo® customers rely on simple and low-investment measures such as shutdown plans, adjustments to operating parameters, and monitoring of relevant consumers, among others, to obtain short-term cost relief over the winter. The exchange made clear that EnEffCo® already provides extensive support for these tasks and measures.

Waste heat is the focus

For long-term measures, companies are focusing not only on PV and biomass systems for their own energy generation, but also on the potential of waste heat utilization, heat recovery and the use of heat pumps. Roland Berger, Managing Director, expressed his satisfaction with the planned projects:

“I am pleased that the topics of waste heat and heat recovery are now becoming more of a focus for companies. We still see a lot of potential here in practice, e.g., using waste heat from process exhaust air to generate heating and process heat or recovered energy for the refrigeration supply, for example. Although the measures are technically demanding, they are easy to manage in the medium term in terms of complexity and are highly attractive both ecologically and economically.”

Roland Berger, Managing Director and Partner, ÖKOTEC Energiemanagement GmbH

EnEffCo® has been an interal player on the market since 2013 and is the set solution at more than 100 manufacturing companies and 1,000 commercial sites in Germany and abroad, including BMW, DUO PLAST, Mercedes-Benz, Kerrygold, Rockwool and Speira.

A basic EnEffCo® installation can be individually upgradable. For a more specific data management, the increase of efficiency, the flexibilization of loads and the energy management of globally operating companies, there are currently 15 modules that facilitate and expand the application depending on the needs and objectives.

Images: ÖKOTEC Energiemanagement GmbH

Your contact

Dr. Hans Rüdiger Lange

Head of EnEffCo® Technology & Product Management