Aluminum Manufacturer

Speira GmbH

Energy management and production analysis

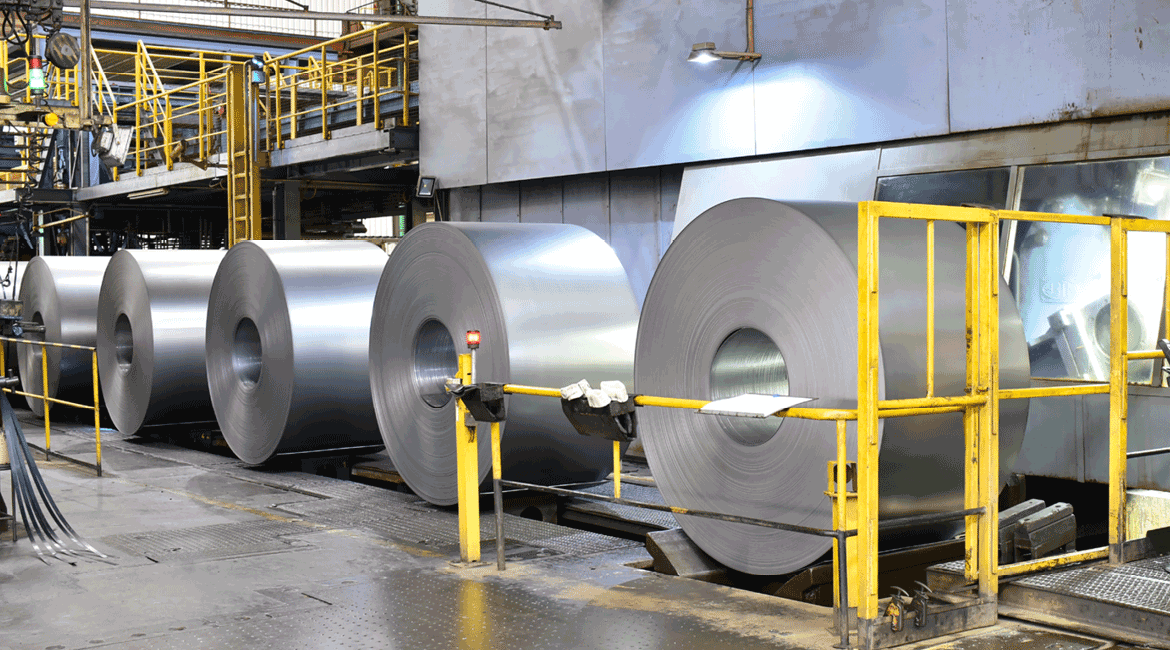

Speira has been using EnEffCo® at its Grevenbroich factory site since 2016 with more than 500 license data points. The aluminum manufacturer was a partner in the CO2realtime research and development project.

The Challange

Speira (formerly Hydro) produces rolled aluminum products in Germany and Norway and employs around 5,000 people. The Grevenbroich plant is the world´s largest aluminum rolling mill. Due to increasing customer needs, Speira was on the lookout for a software application that could serve as a traditional energy management solution while also enabling specific types of analysis to be performed.

“EnEffCo® is a comprehensive energy management system that tracks and visualizes selected energy and process data, thus allowing us to calculate product specific carbon footprints and KPIs.“

Dr. Karsten Kober

Head of Energy Management

The Solution

- EnEffCo® now enables the high resolution management of energy consumption, including the analysis of complex production activities.

- ÖKOTEC developed a custom measurement and KPI system that takes site specific factors into account, thus allowing Speira to monitor and assess production and utility systems, as well as generate automated reports.

- The comprehensive data that are furnished as part of the CO2Realtime project enable the determination of product specific KPIs, thus providing an improved overview of various processes in the value creation chain.

Benefits

- Energy management and energy efficiency: Uniform system for tracking energy data from various sources, thus enabling monitoring, analysis, benchmarking, and the optimization of energy efficiency.

- Savings: Monitoring the success of energy saving measures; identifying new potential for energy savings; reduced time requirements for reports, analyses, etc.

- Management & Compliance: Assurance of compliance with the ISO 50001 standard as well as fulfillment of customer requirements.

- Sustainability: Environmentally relevant and transparent KPIs as well as precise data for reports.