R&D project of ÖKOTEC and RWTH Aachen LTT

Food Pinch: Energy saving through dynamic pinch control

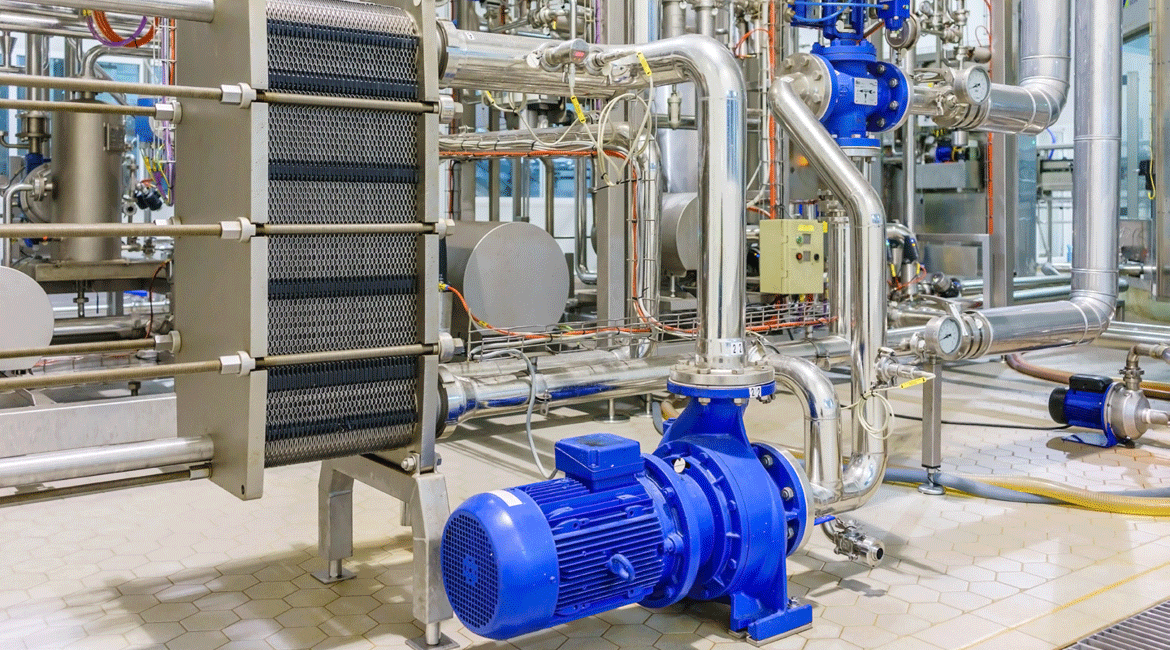

ÖKOTEC and RWTH Aachen LTT are developing solutions in the Food Pinch research and development project to intelligently connect heat sources and sinks in the food industry. Automated control makes it possible to respond to the dynamic processes in food production and to save energy permanently.

Automated control makes it possible to respond to the dynamic processes in food production and to save energy permanently.

Classic pinch analysis with fixed pinch point design has limited application in the food industry due to constantly changing temperature levels and discontinuous heat and cold flows. Together with users from Nestlé Wagner, Nestlé Maggi and Westfälische Fleischwarenfabrik Stockmeyer, we are rising to the challenge and developing pinch analysis into a dynamic approach.

CO2 savings of 15-25 percent possible for industrial partners

“Our goal is ecologically and economically optimized control of the cooling and heating flows. We consider annual CO2 savings of 15 to 25 percent to be realistic if we implement the planned dynamic and automated control at the plant groups under consideration at our industrial partners.”

Dr. Christoph Zschocke, Founder, Managing Director of ÖKOTEC and initiator of the project

Both the increased environmental awareness of producers and consumers and the enormous pressure on prices are placing ever greater importance on the subject of energy efficiency in the food industry. Reducing energy consumption is one of the most important optimization approaches – especially for globally active companies like Nestlé and Stockmeyer. Processes such as cooking, baking, freezing and cooling have high heating and cooling requirements. Every year, heating and cooling applications in the German food industry account for more than 11 million tons of CO2 emissions. And this is precisely where Food Pinch comes in, to identify and leverage potential savings.

The basis for this is provided by the dynamic pinch methodology. However, it will not only be used for planning, as in the classic variant, but also for controlling the plants. With the help of our EnEffCo® energy efficiency software, the dynamic pinch control will then automatically control from which sources the required heating and cooling for the various applications comes – in real time and adapted to the dynamic processes of the food industry. As a result, the heating and cooling networks and software-based control can leverage energy-saving potential that would not be achievable without dynamic pinch control.

Control of plants and processes through dynamic pinch methodology and innovative digital platform

In the Food Pinch project, it is not only the heating and cooling flows that are optimized. EnEffCo® acts as a digital platform to integrate and network relevant process technologies. This enables further development from classic to digital energy management. Stricter requirements from ISO 50001:2018, such as proof of continuous improvement, can thus be easily met. The systematic, scientifically validated approach of Food Pinch also enables a high degree of transferability to other company sites.

Our ÖKOTEC experts can draw on a long history of research and development in the development of Food Pinch: Our energy efficiency software EnEffCo® has been successfully on the market since 2013 and also provides the crucial basis for the necessary plant monitoring at Food Pinch. Our key figure methodology enables a systematic and valid approach to record and analyze the plants and plant systems. Building on EnEffCo®, ÖKOTEC and Fraunhofer IPK have already achieved promising results for the automatic control and regulation of plants with the EnEffReg research and development project, which will be completed in fall 2019. In the pilot project, the results of which are being used and further developed in Food Pinch, savings of 10 to 30 percent were achieved.

Food Pinch is a four-year research and development project funded by the German Federal Ministry of Economics and Technology.

Funding code: 03EN2031A

More information

Your contact persons

Dörthe Hoffrogge (doerthe.hoffrogge@ltt.rwth-aachen.de; +49 (241) 80-95398)

Hagen Seele (hagen.seele@ltt.rwth.aachen.de; +49 (241) 80-95986)

The Chair of Technical Thermodynamics (LTT) at RWTH Aachen University focuses on the development of system analytical methods and technical components for energy systems, as well as theoretical and experimental research of fluid material systems.

Image: NavinTar/Shutterstock.com